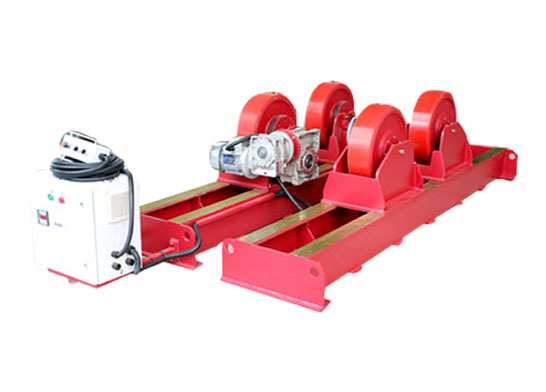

Self Aligned Rotator

Self Aligned Rotator

Sailent Features:

Heavy Duty Structure made out of fabrication steel.

Extremely robust and vibration free.

Stress relieved and precision machine.

Highly stable and accurate rotation even at low speeds.

Back-lash free gear box ensures jerk free rotation.

Sealed roller / ball bearings for long service life without maintenance.

Sturdy rollers of Steel or PU molded as per capacity & application.

Unique design to self aligns rollers without free adjustment.

Accommodates oval or irregularity of the work piece.

Irrespective of diameter job remains central to the frame of the rotator avoiding unnecessary adjustment of welding head.

Single set consists of Drive unit and Idler unit.

Optional Anti-Drift mechanism facility available.

Suitable for interfacing with NC or CNC controllers.

Heavy duty motors of 100% duty cycle.

Heavy duty VFD (Variable Frequency Drive) for continuous operation without overheating and tripping.

Supply input 380 - 415 VAC / 3-Phase / 50-60 Hz.

Applications:

Medium and Heavy duty application like API Pipes, Storage tank, Pressure vessel, Bullets, Condensers, Barrels, Heat exchanger etc.

Suitable for TIG, MIG, MAG, Plasma welding.

Also for SAW, Strip cladding and PTA welding.

Multi-application like Radiography or UT testing, Finishing, Inspection, Assembling, Cutting etc.

Technical Specifications:

| Self Centering / Alignment Type | ||||||||

|

Model |

Capacity (Ton) |

Roller Dia (mm) |

Roller Width (mm) |

Job Dia (mm) |

Motor Power (kw) |

Roller Linear Speed |

Speed Control |

|

| min | max | |||||||

| APWR05S | 5 | 250 | 100 | 250 | 2500 | 2 x 0.75 |

6 m/hr to

60m/hr or 1.6mm/sec to 16mm/sec |

AC Motor Gear with VFD |

| APWR10S | 10 | 300 | 120 | 320 | 3200 | 2 x 0.75 | ||

| APWR20S | 20 | 350 | 150 | 500 | 3800 | 2 x 0.75 | ||

| APWR40S | 40 | 400 | 160 | 600 | 4500 | 2 x 1.5 | ||

| APWR60S | 60 | 450 | 180 | 750 | 5000 | 2 x 2.2 | ||

| APWR80S | 80 | 450 | 240 | 850 | 5500 | 2 x 3 | ||

| APWR100S | 100 | 500 | 240 | 1000 | 6300 | 2 x 3 | ||

| APWR150S | 150 | 500 | 2 x 200 | 1000 | 6300 | 2 x 4 | ||

| Conventional Bolt Type | ||||||||

|

Model |

Capacity (Ton) |

Roller Dia (mm) |

Roller Width (mm) |

Job Dia (mm) |

Motor Power (kw) |

Roller Linear Speed |

Speed Control |

|

| min | max | |||||||

| APWR02B | 2 | 200 | 80 | 150 | 2000 | 2 x 0.18 |

6 m/hr to

60m/hr or 1.6mm/sec to 16mm/sec |

AC Motor Gear with VFD |

| APWR05B | 5 | 250 | 120 | 250 | 2800 | 2 x 0.37 | ||

| APWR10B | 10 | 300 | 130 | 300 | 3200 | 2 x 0.55 | ||

| APWR20B | 20 | 350 | 180 | 500 | 4500 | 2 x 1.1 | ||

| APWR40B | 40 | 400 | 220 | 500 | 5000 | 2 x 1.5 | ||

| APWR60B | 60 | 450 | 2 x 180 | 500 | 5000 | 2 x 2.2 | ||

| APWR80B | 80 | 450 | 2 x 180 | 800 | 6000 | 2 x 3 | ||

| APWR10B | 100 | 500 | 2 x 200 | 800 | 6000 | 2 x 3 | ||

| APWR160B | 160 | 600 | 2 x 200 | 800 | 6000 | 2 x 4 | ||

| APWR200B | 200 | 700 | 2 x 250 | 800 | 6500 | 2 x 5.5 | ||

| APWR300B | 300 | 800 | 2 x 300 | 800 | 6500 | 2 x 5.5 | ||

| APWR500B | 500 | 800 | 2 x 350 | 1000 | 8000 | 2 x 7.5 | ||

| APWR800B | 800 | 900 | 2 x 400 | 1000 | 8000 | 2 x 11 | ||

| APWR1200BB | 1200 | 1000 | 2 x 480 | 1000 | 8000 | 2 x 15 | ||

| Conventional Lead Screw Type | ||||||||

|

Model |

Capacity (Ton) |

Roller Dia (mm) |

Roller Width (mm) |

Job Dia (mm) |

Motor Power (kw) |

Roller Linear Speed |

Speed Control |

|

| min | max | |||||||

| APWR02L | 2 | 200 | 80 | 150 | 2000 | 2 x 0.18 |

6 m/hr to

60m/hr or 1.6mm/sec to 16mm/sec |

AC Motor Gear with VFD |

| APWR05L | 5 | 250 | 120 | 250 | 2800 | 2 x 0.37 | ||

| APWR10L | 10 | 300 | 130 | 300 | 3200 | 2 x 0.55 | ||

| APWR20L | 20 | 350 | 180 | 500 | 4500 | 2 x 1.1 | ||

| APWR40L | 40 | 400 | 220 | 500 | 5000 | 2 x 1.5 | ||

| APWR60L | 60 | 450 | 2 x 180 | 500 | 5000 | 2 x 2.2 | ||

| APWR80L | 80 | 450 | 2 x 180 | 800 | 6000 | 2 x 3 | ||

| APWR100L | 100 | 500 | 2 x 200 | 800 | 6000 | 2 x 3 | ||

| APWR160L | 160 | 600 | 2 x 200 | 800 | 6000 | 2 x 4 | ||

| APWR200L | 200 | 700 | 2 x 250 | 800 | 6500 | 2 x 5.5 | ||

| APWR300L | 300 | 800 | 2 x 300 | 800 | 6500 | 2 x 5.5 | ||

| APWR500L | 500 | 800 | 2 x 350 | 1000 | 8000 | 2 x 7.5 | ||

| APWR800L | 800 | 900 | 2 x 400 | 1000 | 8000 | 2 x 11 | ||

| APWR1200L | 1200 | 1000 | 2 x 480 | 1000 | 8000 | 2 x 15 | ||